Are Madden Sample Coolers the Best Bang for your Buck?

December 7, 2015 by Aaron Rhoade

“Largest heat transfer surface, per unit of cost, of any sample cooler”– Competitor on their Sample Cooler Line

Probably depends on the year and conditions of supply chain if we’re all honest, but in any case, we’d argue our line is on par with any of our competitors’ pricing. This blog idea was written due to a combination of coming across this marketing statement and having heard from our distributors that our sample coolers are the lowest in cost.

We wouldn’t claim this as a norm. Madden typically competes in this industry via quality, dependability, and responsive customer service, while maintaining competitive pricing, not best pricing. When it comes to price we usually hear things like “cost effective”, not “least expensive”. So in this case we thought why not use it as an excuse to share more on our sample cooler product line.

This is a blog intended to explain what exactly sample coolers are, our construction of Type 1 and Type 2 liquid sample coolers, and reasons to buy a Madden Sample Cooler.

Madden Sample Coolers Overview

Madden industrial sample coolers are used in many applications to cool hot liquids to temperatures suitable to be handled and tested. These miniature heat exchangers are designed to cool intermittent “grab” samples as well as continuously cooling samples. The sample coolers achieve temperature reduction by a transfer of heat… let’s take a closer look.

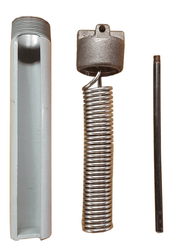

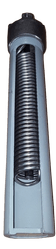

Madden has two types of sample coolers, Type 1 and Type 2. If necessary, both of these units are able to be completely disassembled for cleaning or repairing with common tools. They use either copper or 316 stainless steel coil to run the sample through a shell which contains the constantly replenishing cooling water.

| Type 1 | Type 2 |

|  |

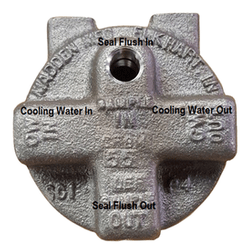

| Madden Type 1 sample cooler models have all the piping connections for the sample and the cooling water on the threaded cap on the top of the sample cooler shell. All coils are 1/4” OD tubing, and all piping connections are 1/4” NPT. Cooling water enters on the left and exits opposite on the right. The “sample in” connection is vertical on the top, and the cooled sample exits from the spout. | Madden Type 2 sample cooler models offer both 1/4” and 3/8” OD tubing coils. Sample connections are 1/4” NPTF and are made on the top plate. Cooling water inlet and outlet connections are 3/8” NPTF located on both the top and bottom plate. |

Function of Heat Transfer/Exchange

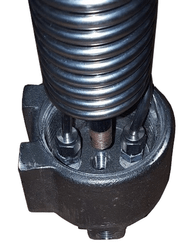

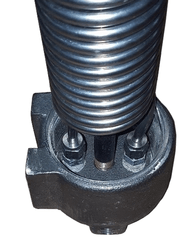

The following is intended to show how the heat transfer happens by explaining the construction of a sample cooler (Type 1 Shown)

It is critical to the operation of a Type 1 Madden sample cooler to have the sample and cooling water flowing in the right direction (labeled on the top cap). Reversing the flow, of the cooling water in particular, will lose the intended function of the Type 1 liquid sample cooler and here’s why…

It all has to do with the long reverse flow tube we put in the center of the sample coil. This reverse flow tube takes the entering cooling water down to the bottom of the shell. This makes avoids any possible stagnant water. Fresh cooling water will constantly and consistently be flowing through your Type 1 sample cooler.

You can also use this visual to get an understanding of how and where the heat transfer takes place. Pretty simple. As the cool water is entering, so is the hot sample. The hot sample will give off heat through the coil to the cooling water. As a result the sample will leave much cooler than it entered; and the cooling water will in return leave warmer than it entered.

| Type 1 Construction | |

1. | 2. |

3. | 4. |

5. | 6. (View looking down on cap) |

Type 2 sample coolers function the exact same way except, since it has two caps/heads, each has been given one NPT input/output connection. Type 2 sample coolers can have cooling water enter or exit in either direction.

Features/Things to Note

- Madden sample coolers are rated for samples with a maximum temperature of 750°F/399°C

- Alternative coil material available on special request for Type 2 sample cooler.

- Sample coolers can be used as miniature heat exchangers, for example, as a pump seal flush cooler.

- Copper has a higher BTU’s/hr capacity than stainless steel. Layman’s terms, copper allows for easier transferring of heat than stainless steel.

- Remember our sample coolers can be easily disassembled for maintenance. Keep your coils free of buildup and debris for maximum performance and life span of the product.

- We can do calculations for you to determine feasibility and the resulting temperature of a sample you would like to cool. We just need to know the sample temperature in, desired sample temperature out, sample’s expected flow rate, cooling water temperature, and cooling water flow rate. We use these numbers to determine the required BTU’s/hr and then pair it up with the appropriate Madden sample cooler that is capable of cooling that amount of BTU’s/hr.

- General rule of thumb: if your application does not exceed our sample coolers’ capabilities, these liquid sample coolers can generally bring the sample to within 10°F of the cooling water temperature.

Conclusion

We truly believe in and stand behind all of our products’ quality. So hopefully after reading this article readers can now understand our excitement at this marketing opportunity that arose from a competitor’s claim and one of our distributor’s statements. We know our products have great dependability and durability, being told our price is among the lowest is simply a bonus selling point. We do not manufacture to be the cheapest, we manufacture products to meet high performance standards and last a long time, our pricing is established based on that criteria.

So, if you have an application using hot liquids and need that to be cooled for any reason, give us a call at 574-295-4292 and/or shoot us an email at info@maddenep.com and we’ll see if we can find a sample cooler for you at a great price!