Boiler Blowdown Tanks

BLOWDOWN TANKS FOR INTERMITTENT BOTTOM BOILER BLOWDOWN

- INDUSTRY SIZING EXPERTS – Madden has over 65 years of experience with designing boiler blowdown tanks. We can assist in designing vessels to meet NB-27 standards as well as recommend more cost effective sizes which will still be safe and appropriate per your boiler room’s blowdown parameters.

- COMPLETE BLOWDOWN SOLUTIONS – A blowoff vessel is one part of a boiler room blowdown system. Madden not only designs common tanks for multiple processes, we also design and fabricate full cold water tempering solutions to ensure the system never drains above 120 deg F.

- CONSTRUCTION – ASME Div I, Sec VIII Vessels, 50 PSI DWP @ 450 deg F, with National Board serial number included.

- MORE CALCULATION & DESIGN SUPPORT – Madden can also assist in sizing a quenching water spool and/or include other blowdown processes to be sized into a single tank.

- ENGINEERING DATA SHEET – A generic BD Tank data sheet designed to help engineers or reps specify a tank design for their customers and/or for Madden to quote to.

- Or, CONTACT US to start your boiler room’s next traditional blowdown tank design.

- OVERVIEW

- DATA REQUIRED FOR SIZING

- PRODUCT LINE

- RESOURCES

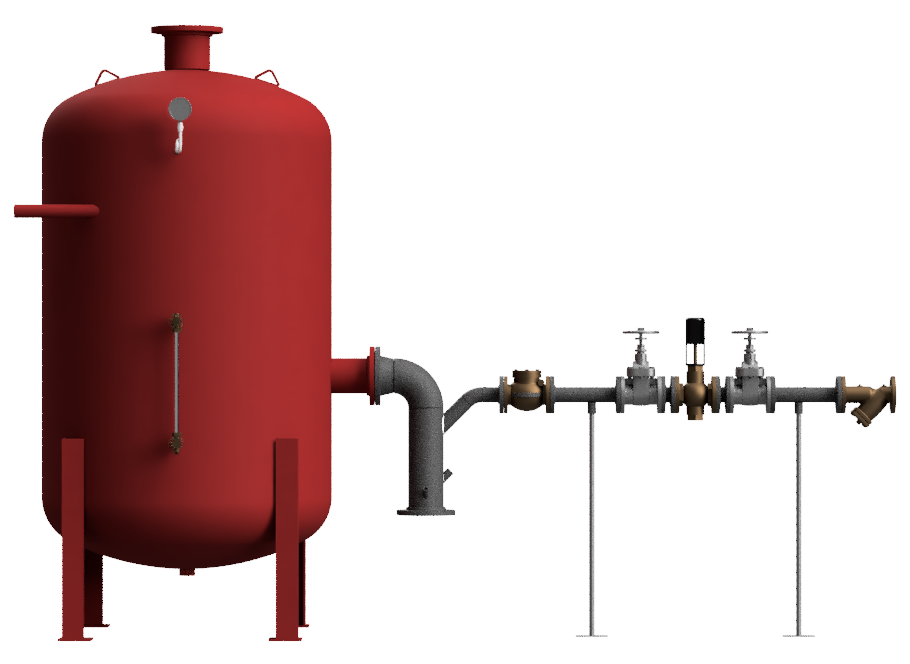

ASME blowdown tanks for boilers are used as an alternative system for cooling the bottom boiler blowdown. These large tanks retain the blowdown water volume from one blow after the flash steam has been vented to the atmosphere and allow the water to cool down by natural convection over a 6-12 hour period. The cooled water will be below 140° Fahrenheit when it is displaced by the next blowdown and forced out of the overflow drainpipe.

Shell length and connections size dimensions can be changed to meet the application requirements for the specific boiler as determined by design rule calculations.

Sizing of tank and connections should be determined using National Board design rules for blowoff tanks.

Custom Blowoff Tanks

Madden can also design blowoff tanks to meet your specifications. We follow the “National Board Rules and Recommendations for the Design and Construction of Boiler Blowoff Systems”. If you have requirements that go outside of our standard product line, let us know your requirements and we’ll design a unit for your consideration. Check out the picture of what we called a BD9600, this unit was over 8 feet tall. No matter the boiler size, if you need an ASME coded tank for boiler blowdown water Madden Engineered Products has you covered.

Why a Blowoff Tank is Needed

In summary, by Madden: boiling water causes scaling and deposits to form resulting in a less efficient boiler and a less efficient boiler means increased costs. Because of this, boilers need to be intermittently, and sometimes continuously, flushed of a certain percentage of their water. Therefore, boiler rooms need blowoff tanks to meet legal regulations and to safely dispose of hot, dirty boiler blowdown.

In more detail, information from The National Board of Boiler and Pressure Vessel Inspectors: The treatment of boiler water is an integral part of boiler operation, used to control scaling, corrosion, and deposits. Boiler water treatment often leads to the formation of solid particles that are initially suspended in the boiler water. Solids concentrated in boiler water tend to promote foaming and scaling with a resultant loss of heat transfer which may result in overheating of the boiler tubes. Solids also may settle to the bottom of the boiler to form sludge. “Blowing off” part of the boiler water is a means of removing solids from the water while controlling boiler water levels.

The primary function of the blowoff system is to provide a safe means of controlling boiler blowoff water. This includes a reduction in both pressure and temperature to limits acceptable for safe discharge into a sewer, drain system, or other areas. The usual practice, therefore, is to discharge the water into a vented vessel where it may be allowed to cool, or mixed with cold water to reduce the temperature and pressure to acceptable discharge levels.

Discharge of high-temperature water from a boiler blowoff system can present a hazard to personnel and may also damage sewers or drains. Blowoff pressure should not exceed 5 psi. Typically, the maximum acceptable water temperature for discharge into a sewer system is 140°F. Requirements of the Environmental Protection Agency, or local ordinances, may require lower temperatures.

The full article can be read here. Citation: The National Board of Boiler and Pressure Vessel Inspectors (n.d.). Retrieved June 24, 2016, from http://www.nationalboard.org/

Data required for sizing calculations:

- Blowdown pipe size and estimated equivalent straight length to the tank.

- Boiler steam drum diameter & length. If it is not a watertube type boiler, confirm average time boiler operator will blowdown (typically 15-30 seconds).

- Boiler operating pressure.

Construction: ASME Section VIII, Div. 1, 50 PSI DWP @ 450 Deg F, with National Board serial number

At this time, Madden builds all blowdown tanks to order. Conceptual “pre-designed” model numbers are available in our Blowdown Tank data sheet (click the link near the top of this page or go to the “Resources” tab). The conceptual designs are intended to streamline design conversations and/or for engineers to use as a placeholder during preliminary design stages of a soon to be publicly bid project.