How to recover and reuse heat from boiler blowdown water: Part 2, focusing on Madden’s lower vessel of a HV model heat recovery system, the heat exchanger

December 1, 2017 by Aaron Rhoade

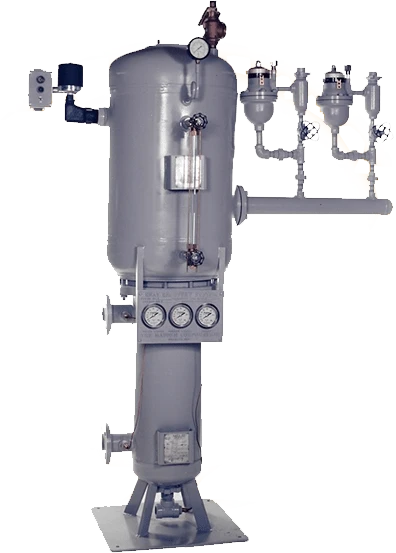

In our most recent blog posting we discussed how Madden Engineered Product’s vertical boiler blowdown heat recovery systems recover heat from your boiler’s continuous surface water blowdown. In that blog we focused on the operation of the upper portion, the flash tank, and how it results in saving on fuel costs.

In this blog post we are now going to discuss how the lower vessel, the heat exchanger, operates, resulting in fuel savings.

Keep in mind, with some of our competitor’s heat recovery products, you have to buy two separate systems. They sell a flash tank and then the heat exchanger as separate units, which can be built together on one skid, but in either case, floor space can become an issue. We find our design more effective, as it saves floor space in your boiler room, as well as cost on the initial installation.

Recovering heat from boiler blowdown, recap

The main reason for disposing of your boiler’s water is to keep the water that is being boiled as clean as possible. Water that is free from suspended and dissolved solids, as well as scale build up, boils more efficiently. Scale build up on the water or fire tubes in your boiler will hinder the heat transfer process from the burning fuel to the water. Suspended and dissolved solids can form a foamy layer at the top of the water line, which hinders in the steam evaporation process; and there you get the exact reason continuous surface water blowdown is a necessary boiler process.

Continuous surface boiler blowdown is a very important part of the boiler room’s operation. Depending on the size of your boiler operation, continuous surface blowdown is often a necessity, not just an optional feature of the boiler; whether you want to recover heat from the boiler water or not, you must buy blowdown tanks to legally handle this water. Which leads us to ask, in that case, why not get a heat recovery system instead of just a blowdown tank?

Madden’s flash tank, recap

When you continuously blowdown hot surface water from the boiler, the first thing that is needed is a low pressure flash tank designed to handle the flash steam that will occur. When hot water goes from high pressure to low pressure, a percentage of it wants to evaporate into steam upon entering the low pressure vessel. Ideally, this steam is sent to the D/A tank to be used to heat up boiler make up water and to help remove oxygen from the boiler make up water.

For more information on how our systems reuse the steam in the blowdown to save on fuel costs, see our previous article: Part 1, focusing on Madden’s upper vessel of a HV model heat recovery system, the flash tank.

Now, let’s discuss what happens with the remaining hot, dirty condensate water after some of it has flashed to steam.

Recovering BTU’s from hot condensate to be used in your boiler makeup water: Madden’s lower vessel in their boiler blowdown heat recovery systems, the heat exchanger

The top of Madden’s heat exchanger has a ball type float valve which allows the upper flash vessel to remain under pressure, forcing the flash steam into the D/A tank. After the remaining hot condensate rises to a level that actuates the float valve, the hot water then continuously goes to drain through the lower vessel. And what is the lower vessel exactly? It’s a shell and tube heat exchanger.

The hot condensate goes through a self-draining, copper or stainless steel coil before leaving the heat recovery system to ultimately be sent to the sewer. While the hot dirty boiler water is passing through the coil, cooling water is sent through the unit on the shell side. Heat from the hot boiler water transfers through the coil and into the cooling water. Thus the boiler water will drain at a safe legal temperature of 140 degrees or less, and the cooling water will pick up a significant amount of heat on its way to feeding the boiler feed water tank.

This system utilizes everything you are already using in your boiler operation. And it is completely mechanical. These features make Madden’s system a truly efficient machine. No electronic system, no fuel involved, no moving parts (less the float valve), just a simple, durable piece of equipment designed to safely dispose of dirty, hot boiler water, while recovering what would otherwise be wasted heat, BTU’s.Most Madden blowdown heat recovery systems have a payback period of less than one year. In larger applications, it isn’t uncommon to have a unit even pay itself off in as little as 4-6 months. The fuel your boiler burns to heat water is costly, and it is burned throughout the day. Sending warmer water into the boiler, instead of just ground temperature water, adds up in cost savings, day in and day out, year in and year out.

Highlights of the Madden heat recovery systems, things to know:

- Copper coils have a higher heat transfer capacity per square foot, than stainless steel coils; this can potentially lead to greater savings depending on the application. However, in most cases, stainless steel coils will be able to handle the blowdown system’s maximum potential BTU exchanger rate, and therefore is a great option for added durability.

- Our vertical, self-draining coil design means no regular maintenance or cleaning is required in our units.

- Madden can provide you a performance and savings calculation to help with your decision. We can show you how many BTU’s your make up water will pick up per hour/day/year, and if provided a cost per Therm, we can show the savings down to the cent per hour/day/year.

- Most Madden boiler blowdown heat recovery systems allow the cooling water to increase about 10 degrees from entering the shell side of the lower vessel to exiting the shell. This means every minute of the day, your boiler is working with water that is 10 degrees closer to boiling than it would otherwise.

Conclusion

Madden heat recovery systems for boiler surface blowdown water save you money and are one of the most compact systems and easiest to install on the market. They pay for themselves, so if you have the funds available in your current or upcoming budget, give a Madden distributor/rep a call to discuss boiler blowdown heat recovery.

The employees at Madden, and our great distributor and rep team are here to further our stance that Madden products are some of the simplest and most durable on the market, which equate to peace of mind. Building and designing a boiler room, or adding equipment to it can be a daunting task you want to avoid and put off. Allow the Madden team and their reps to show you how relatively headache free it can be to get a cost saving recovery system into your boiler room.

Thanks for reading our article, and as always, have a great day!

(PH: 800-369-6233, email: info@maddenep.com)